the HARADA method : a Toyota Lean tool to improve human self reliance

the Harada method is developed from Lean by Toyota to limit human skills wastes. with tools for goals and purpose setting, improvement, actions and evaluation

the Harada method is developed from Lean by Toyota to limit human skills wastes. with tools for goals and purpose setting, improvement, actions and evaluation

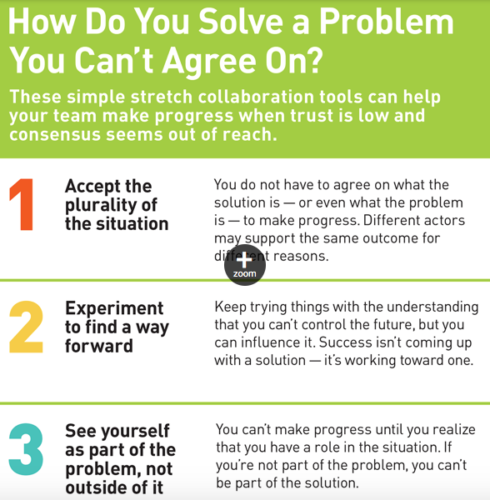

Adam Kahane’s « stress collaboration » process to achieve collaboration when seemingly impossible is very similar to the Value(s) mindset and Interactifs

the book « What is it for ? a system approach for value(s) creation » is edited in April 2018 and presented at the 6th SAVE-Europe conference in Budapest Hungary

Tony Ulwick presents Outcome-Based Innovation andJob-To-Be-Done Theory to design products that answer client needs : great ! But Value(s) tools can help

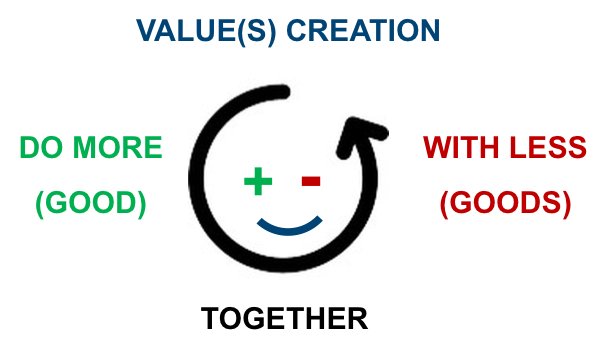

A logo for Value(s) creation : what do you think ?